Loaf Tanks

Norwesco polyethylene loaf tanks are molded of rugged, high-density linear polyethylene (Poly) and are both impact and chemical resistant.

Loaf tanks are designed for many mobile and stationary applications where a rectangular shape is desired, or required by dimensional restrictions.

Ideal for auto detailers, the storage and/or transport of potable water, gray water, most liquid agricultural chemicals, a wide range of industrial chemicals, and custom built equipment where a compact rectangular tank is needed.

Tanks are rated for liquids with a specific gravity up to 1.5, weighing up to 12.5 lbs. per gallon. Customer must verify load carrying capacity of vehicle before placing tank into service. If your application deals with certain caustics, acids, and chemicals, the tough molecular structure of crosslink polyethylene makes it an ideal solution.

Due to the wide range of applications and for added flexibility, tank fittings for Norwesco linear poly loaf tanks must be ordered separately by specifying the size and location of the fittings according to your system design.

Linear poly tanks are molded from 100% FDA approved materials and are therefore excellent for safe storage of potable water and food products, as polyethylene will not impart any taste or residue. The natural opaqueness of linear polyethylene allows for easy viewing of your liquid level.p>

Norwesco poly tanks are UV stabilized and will not breakdown under harsh outdoor weather conditions. These tanks are designed to withstand sustained temperatures up to 120º F, and peak temperatures up to 140º F. To insure the highest quality, all poly loaf tanks have been manufactured according to ASTM D1998-93 standards.

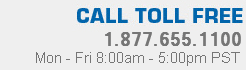

Call toll free today: 1-800-655-9100 to speak to one of our friendly and knowledgeable Norwesco Tank Specialists.

American Tank Company supports the manufacturer’s 3-year warranty dependent on the chemical compatibility of the intended contents with the tank, tank fittings, and fitting gasket materials.

Due to the nature of the rotational molding process, dimensions may vary from what is published and shown on the referenced drawings.

During the delivery process, tanks can pass between several docks and trucks on their way from the factory to the customer. Though not a guarantee, tank wrap “helps” to protect the tanks from getting scuffed and dirty. The best way to avoid cosmetic damage is to set up a will call at the factory and personally handle the tanks yourself.